Step-by-Step Breakdown of the Creative, Engineering & Manufacturing Process

Table of Contents

Creating a successful POP (Point-of-Purchase) display involves a complex, multi-step process. From initial concepts to mass production, the journey requires cross-functional collaboration. The process blends creativity, engineering, and manufacturing to create displays that are visually compelling, functional, and cost-effective.

At Samtop, we guide brands from an idea to a ready-to-ship display that performs seamlessly in-store. Here’s how it all comes together:

The Challenge of Creating a POP Display

When designing a POP display, the key challenges include balancing creativity with structural feasibility and cost-effectiveness. A display needs to be eye-catching and on-brand while remaining functional, easy to assemble, and suitable for mass production. Additionally, the display should stand out in the retail environment, effectively promoting the product while being cost-efficient for the brand.

Why Traditional Methods Don’t Always Work

Many brands face difficulty managing the complexity of creating custom POP displays. It’s easy to get lost in design aesthetics, but without proper engineering and manufacturing processes, even the most beautiful display can fail in terms of function, durability, and cost. For example, a luxury perfume display may require fine materials and unique lighting to evoke a premium feeling, but if the structure is not engineered for stability, it could result in a poor in-store experience. This lack of synergy between design and function can result in a display that looks great but doesn’t perform as expected.

A Streamlined, Collaborative Process from Design to Mass Production

At Samtop, we ensure that every POP display is designed and engineered with both aesthetic appeal and functional integrity. The process starts with a comprehensive briefing, where brand teams outline key objectives, followed by 3D design and visualization to ensure the display aligns with product goals. After that, we move into sampling and prototyping to test materials and construction before entering the mass production phase. During engineering, we optimize the design for cost-efficiency and scalability, ensuring the display is not only visually striking but also structurally sound and ready for high-volume production. Throughout the entire process, we collaborate closely with brand teams to ensure that the display meets both creative and practical needs, delivering a solution that resonates with consumers and fits within budget constraints.

1. Briefing: What Makes a Good POP Display Brief?

A strong POP display brief outlines essential details that will guide the entire process. Your creative or sourcing brief should include:

- Product type(s) & number of SKUs

- Target store type (flagship, mall, pop-up, department store)

- Size & footprint limits (in cm/inch)

- Brand colors, logo, finish preferences

- Special features (lighting, motion, testers, modularity)

- Expected usage: temporary, semi-permanent, or permanent

- Deadline & rollout region (for compliance or shipping planning)

✅ Include visual moodboards or past examples, even if not highly technical — engineers will interpret design elements.

2. Design & 3D Visualization

Once the brief is clear, the design team starts conceptualizing and visualizing the display in 3D. This phase includes:

- Conceptual Rendering: Mood, shape, materials, and proportions.

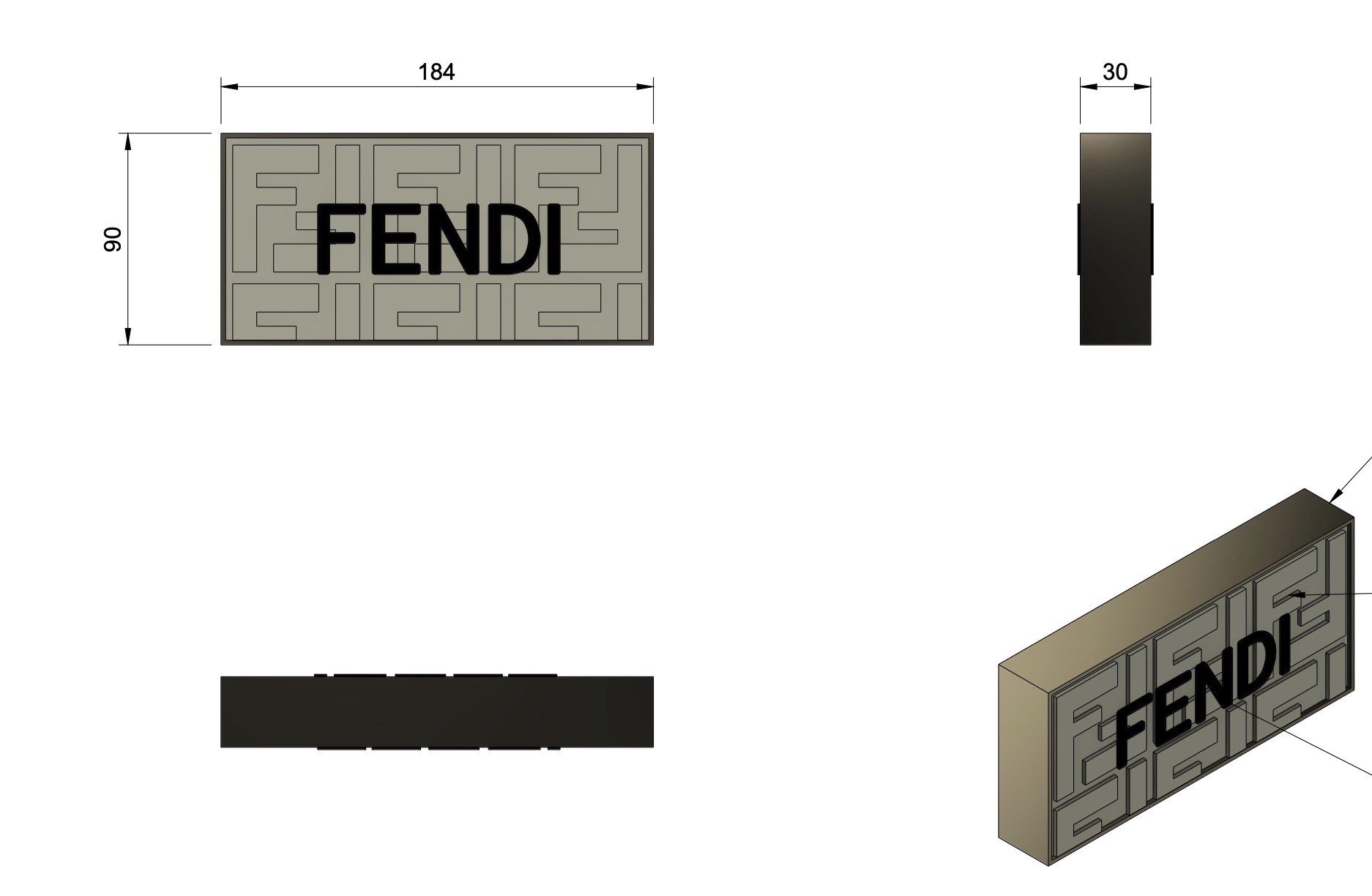

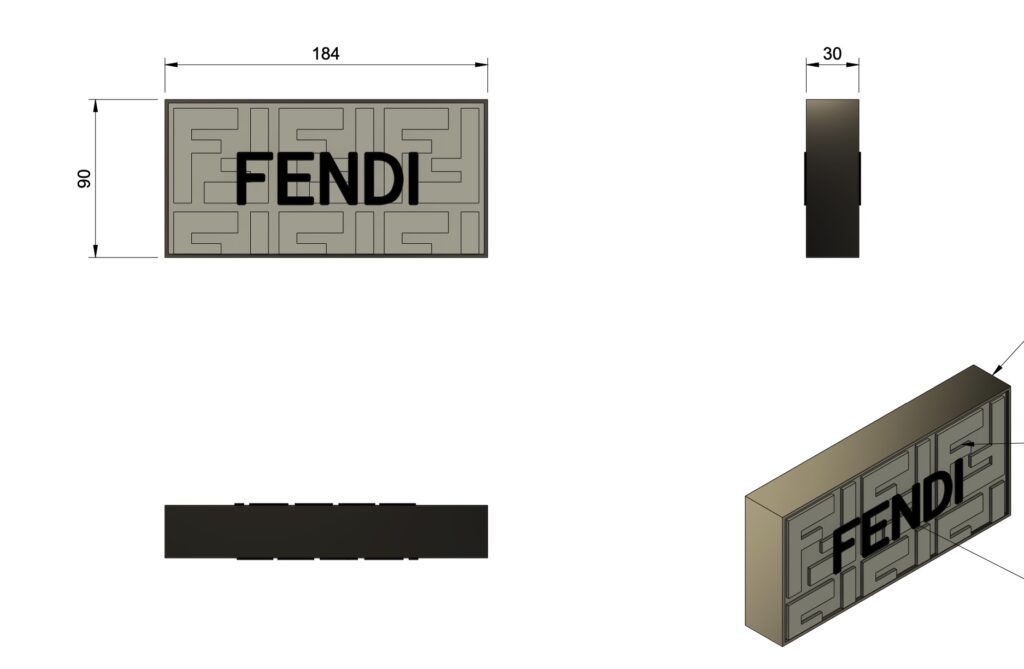

- 3D CAD + Structural Drawing: Realistic layout, part list, and joinery logic.

- Branding Overlay: Logo placement, color zones, and signage.

✔️ Pro Tip: Always review designs in context (e.g., shelf or aisle mockups), not just in isolated white space. This helps ensure that the display will perform well in actual store environments.

3. Sampling & Prototyping

Sampling is essential to validate the design before mass production. During this phase, the design is tested for:

- Materials sourcing: Are surfaces available or substituted?

- Print test: Ensure accurate brand color, sharpness, and logo durability.

- Structural sample: Test assembly, fit tolerance.

- Lighting + wiring: Check power access, glow angle, and battery life.

- Feedback loop: Photo and video reports sent for revisions.

📌 Note: One round of prototyping typically takes 7–15 working days. Complex or premium displays may require multiple rounds.

4. Engineering for Mass Production

Once the prototype is approved, engineering optimizes the display for mass production:

- Adjustments for factory machine sizes: Panel cuts, bends, etc.

- Fastener count reduction: Switch to clip or slot systems.

- Cost balance: Suggest substitutions for internal parts.

- Shipping & assembly format: Plan for knock-down (KD) or pre-assembled formats.

- Tech pack: Finalize the Bill of Materials (BOM), QC checklist, and assembly instructions.

✅ This stage solidifies the exact specifications for final approval and mass production.

5. Mass Production: Scaling Up

After final approval, the production process begins:

- Pre-production Run: Test 5-10 sets for QC and packing efficiency.

- Mass Manufacturing: Order materials, cut parts, and apply surfaces.

- Branding Applied: Print logos, place labels.

- QA + Packing: Spot checks, crate loading, and foam protection.

- Shipping Booked: Labeling, documents, and export coordination.

📌 Note: Allow 25–45 days from approval to the ex-factory date depending on complexity and quantity.

FAQ: Your POP Display Production Questions Answered

Q: Can I skip the prototype to save time?

⚠️ Risky. Skipping the prototype can lead to overlooked structural issues or mismatched finishes. Always prototype at least once.

Q: Can one factory handle both design and production?

✅ Yes — if the supplier has both creative and engineering capabilities, as Samtop does.

Q: What format is used to review engineering drawings?

✅ PDF, CAD (STEP/IGS files), and photo-annotated views for easier approval.

Conclusion: A Great POP Display Is Engineered to Sell

✔️ Start with clear brand goals and constraints

✔️ Collaborate on design + structural feasibility

✔️ Test early through prototyping

✔️ Engineer for scale: packaging, safety, and installation

✔️ Choose partners who understand both storytelling and manufacturing

At Samtop, we turn your POP display ideas into reality — faster, smarter, and with fewer surprises at rollout.

Need Help Turning Your Concept into a Retail-Ready POP Display?

We offer:

- 🧠 Creative-to-factory translation service

- 🧾 Prototyping + costed sampling

- 🔧 Engineering refinement for rollout

- 📦 Knock-down optimization + packing tests